Pouch Features And options

Resealable Zippers

When we open the pouches, sometimes, the food may get bad in a short time, therefore add a zip-locks for your packages is a better protection and better using experiences for end users. The zip-locks also called reclosable or resealable zippers. It is convenient for customer to keep the food fresh and tasted good, it extended time for preservation of nutrients, taste and aroma. These zippers can be used for storing and packaging food of nutrients as well.

Valves or Vents

Meifeng Plastic provides two types of Valves, one is for coffee beans, another is for coffee powders.

And some of the Kimchi packages are also added valves to release the gases.

This added option is for these products will liberative many gases after packed, so, we add a valve to release the gases from the package in order to avoid the explosive. By adding this option, it helps in maintaining the freshness of the products. It also called “aroma valves” as they all the user to smell the product through the valve.

Clear windows

Many consumers like to see the inner contents of the product, and it boost the confidence in buying the products. Therefore, we provide clear window in a pouch for the transparent part of packaging. The sizes and shapes of the window are available for customized. And these add-ons are very popular in the market to help making a good sale.

Tear Notches

Tear notches are helping consumer to open the pouch easily and quickly by hand. It is a pouch with an option pre-cut to coax the consumer initiate the tear-off action immediately. Tear notches provide pouches with ultra-clean and straight pouch openings. Tear notches can be added in variety types of bags.

Handles

Meifeng is offering three different types of handles.

1. Inner Rigid handle

2. Outer Rigid handle

3. Ergonomic handle

These handles are designed to add value and boost consumer convenience. We provide all different styles and sizes so that one can use it for better carrying the product.

Euro or Round Punch Holes

These different types of hole are good to hung and viewed by consumers, and it is easy to display on markets.

1. Euro hole

2. Diameter in 8mm for punch hole

3. Diameter in 6mm for punch hole

Rounded Corners

Rounded corners can be prevented the sharp corners from inflicting injuries while handling them. And it has a good look compare the sharp corners on pouches.

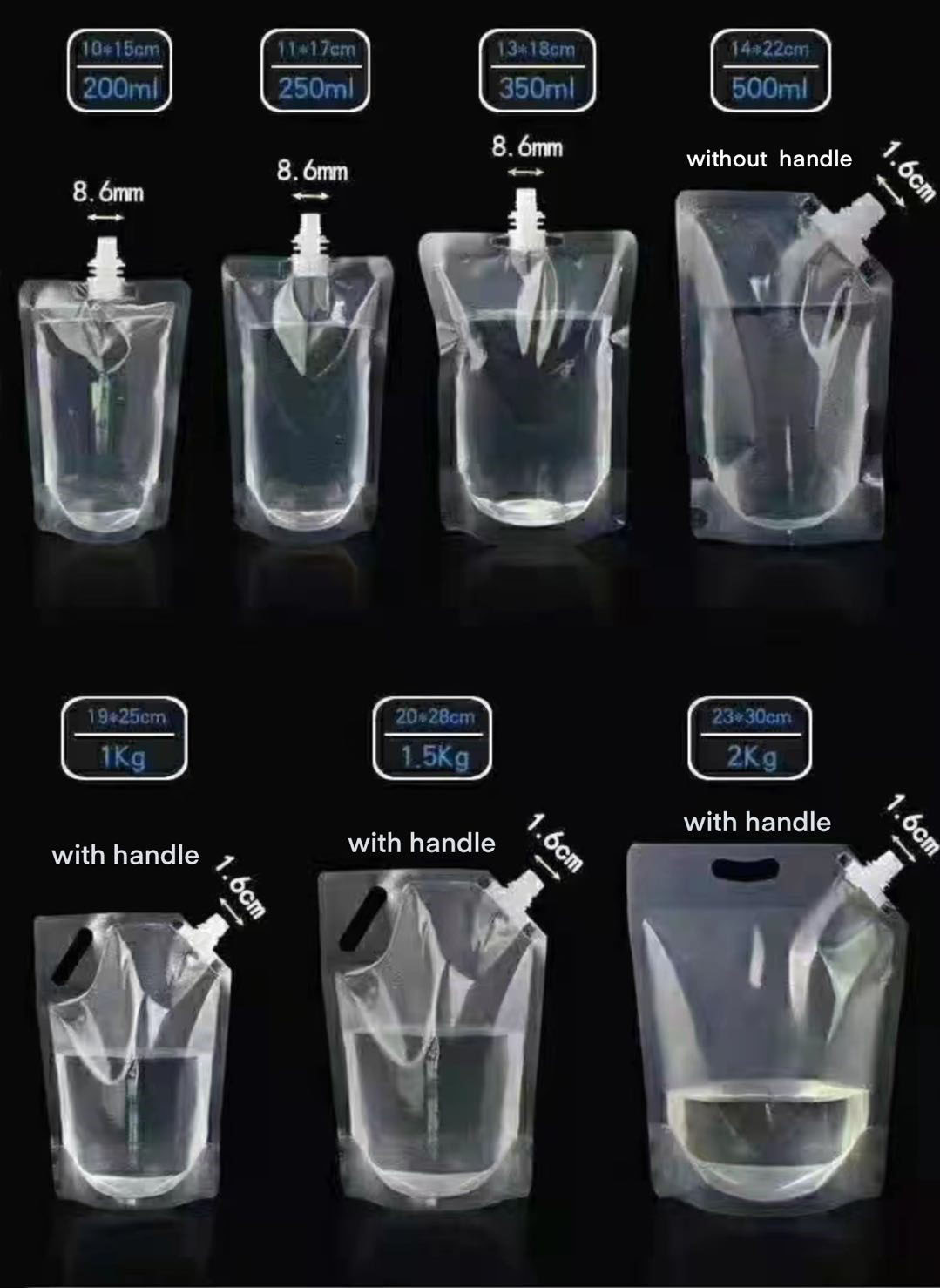

Spout pouches

We have different types of spouts for liquid and half liquid bags. The size of the spout could be adjusted according to the clients needs.

Structures

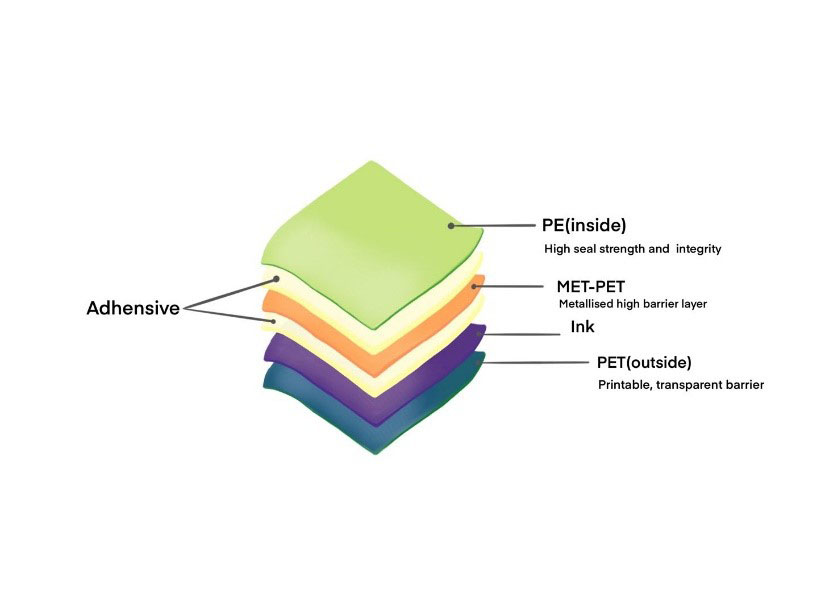

Flexible Pouches, Bags & Rollstock Films

Flexible packaging is laminated by different films, the purpose is to offer a good protection of the inner contents from the effects of oxidation, moisture, light, odour or combinations of these. For commonly used materials structure are distinct by outside layer, middle layer, and inner layer, inks and adhesives.

Outside layer:

The outer printing layer is usually made with good mechanical strength, good thermal resistance, good printing suitability and good optical performance. The most commonly used for printable layer are BOPET, BOPA, BOPP and some kraft paper materials.

The requirement of outside layer is like following:

| Factors for checking | Performance |

| Mechanical strength | Pull resistance, tear resistance, impact resistance and friction resistance |

| Barrier | Barrier on oxygen and moisture, aroma, and UV protection. |

| Stableness | Light resistance, oil resistance, organic matter resistance, heat resistance, cold resistance |

| Workability | Friction coefficient, thermal contraction curl |

| Health safety | Nontoxic, light or odor lessness |

| Others | Lightness, transparency, light barrier, whiteness, and printable |

Middle Layer

The most commonly used in middle layer is Al (aluminum film), VMCPP, VMPET, KBOPP, KPET, KOPA and EVOH and etc. Middle layer is for barrier of CO2, Oxygen, and Nitrogen to go through the inner packages.

| Factors for checking | Performance |

| Mechanical strength | Pull, tension, tear, impact resistance |

| Barrier | Barrier of water, gas and fragrance |

| Workability | It can be laminated in both surfaces for middle layers |

| Others | Avoid of light go through. |

Inner layer

The most important for inner layer is with a good sealing strength. CPP and PE are most popular to use by inner layer.

| Factors for checking | Performance |

| Mechanical strength | Pull resistance, tear resistance, impact resistance and friction resistance |

| Barrier | Keep a good aroma and with a ow adsorption |

| Stableness | Light resistance, oil resistance, organic matter resistance, heat resistance, cold resistance |

| Workability | Friction coefficient, thermal contraction curl |

| Health safety | Nontoxic, odor lessness |

| Others |

Transparency, inpermeable. |