In the plastic flexible packaging system, such as the pickled pickles packaging bag, the composite of BOPP printing film and CPP aluminized film is generally used. Another example is the packaging of washing powder, which is the composite of BOPA printing film and blown PE film. Such a composite film is very firmly bonded because of the application, and it is difficult to separate or the cost of separation is too high, so recycling is of little significance.

If we can replace the current composite packaging of different materials with materials of the same material, the convenience for recycling will be greatly increased. As mentioned above, using the new product BOPE to replace BOPA can make the whole package made of PE material, which is convenient for recycling and is conducive to the development of green and environmental protection of flexible packaging.

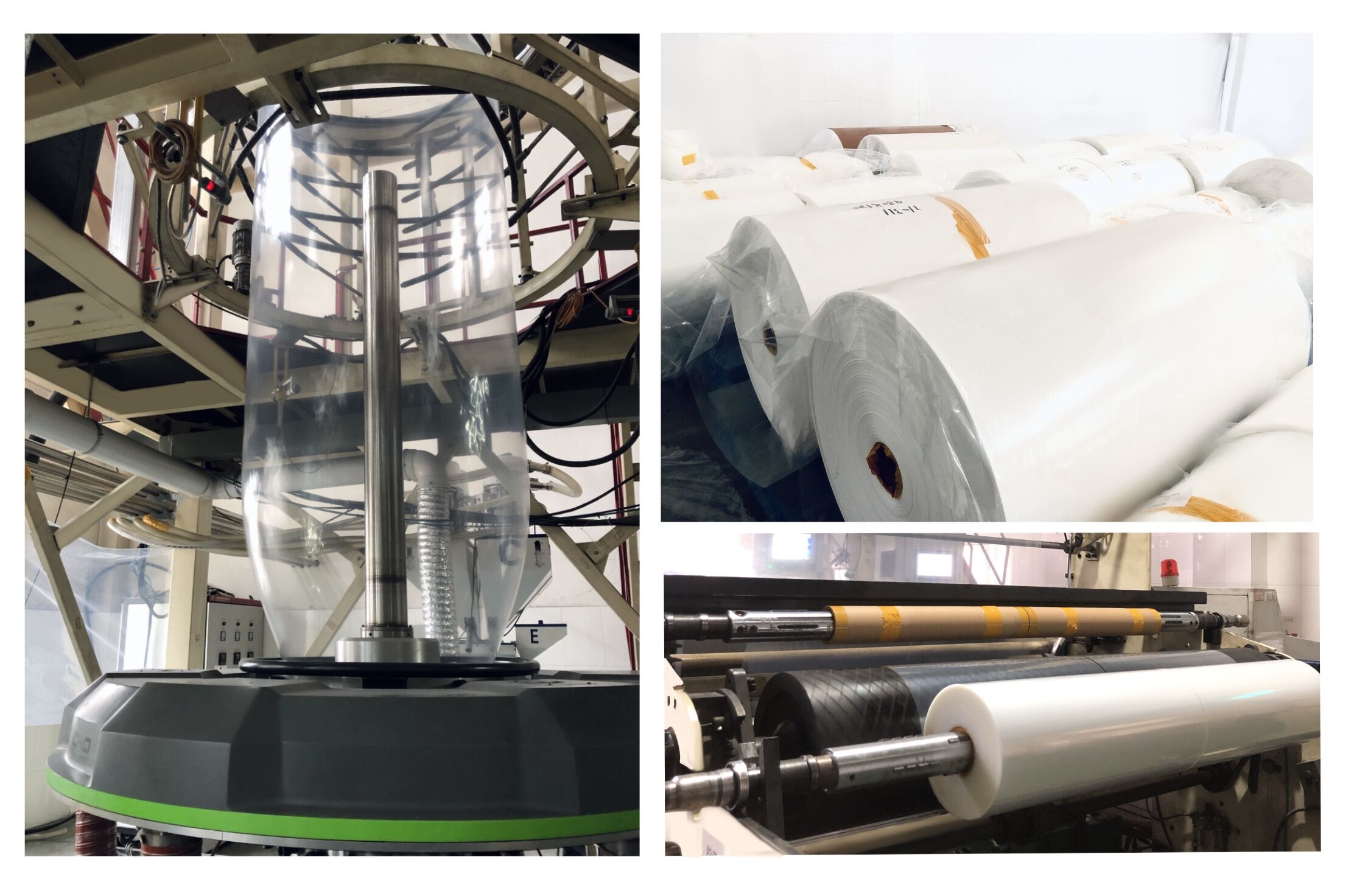

BOPE film is made of polyethylene resin with special molecular structure as raw material, which is formed by flat film biaxial stretching process. The properties of BOPE film have been greatly improved after stretching. Through the design of raw material molecular structure and the research of film stretching technology, Sinopec Beihua Research Institute has developed the first BOPE special material with high stretching ratio and stretching rate in China.

The special material can be produced on the existing BOPP double-drawing production line, which fully meets the requirements of the production line for the stretch film-forming properties of the raw materials, which also makes the large-scale industrial production and application of BOPE possible.

At present, BOPE film has been applied and developed in the fields of daily chemical packaging, food packaging, agricultural film and other fields, and certain results have been achieved. The developed BOPE film applications include heavy packaging bags, food packaging, composite bags, daily chemical bags, white film, etc.

Among them, the application of BOPE composite bag is relatively successful at present. After BOPE is compounded with other substrates, the packaging material has the characteristics of sprint resistance, impact resistance, high strength and low temperature resistance. Due to the high strength of BOPE, it is possible to reduce the thickness of packaging materials. At the same time, the improved packaging strength can also reduce package breakage, reduce packaging waste, and reduce costs.

At present, the most environmentally friendly packaging material related to PE on the market is all PE environmental protection packaging bags.

At present, it is more realistic to use BOPE as the outer layer and CPE or PE blown film as the inner layer and composite all-PE packaging bags. BOPE provides puncture resistance and tensile strength, so the prepared packaging bags are environmentally friendly and easy to recycle. The same At the same time, the material is soft and not easy to be scratched, and can be used in washing powder packaging, maternal and child products, etc. In addition, efforts can be made to develop BOPE’s aluminized film, matt film, and even BOPE’s high shrinkage film.

Our company also responds to the needs of the market and develops all PE environmental protection packaging bags, mainly Food Grade Recyclable Packaging Bags.

Post time: Jun-06-2022