A wide variety of packaging types have appeared in the market today, and many packaging types have also appeared in the plastic packaging industry. There are ordinary and most common three-side sealing bags, as well as four-side sealing bags, back-sealing bags, back-sealing gusset bags, stand-up bags and so on.

Among them, the back-sealed gusseted packaging bag and the four-sided sealed packaging bag are the most likely to be confused, and the two types of bags are often unclear.

Today we will simply learn to distinguish these two kinds of packaging bags:

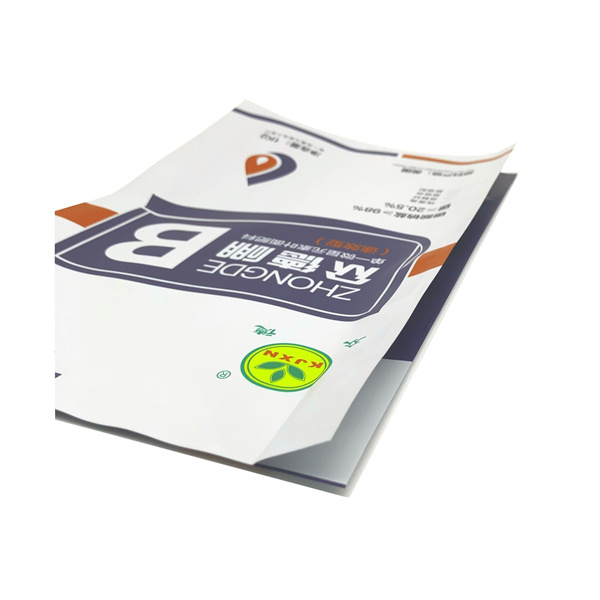

After the four-side sealing bag is formed into a bag, the four sides are all packaged in a heat-sealed bag, usually a whole piece of packaging film is divided into two halves for opposite packaging. Alignment can achieve a good packaging effect. Therefore, both in terms of packaging materials and production equipment, it has high adaptability and stability.

The four-side sealing bag packs the product into a cube shape, and the packaging effect is good. It can be used for food preservation and is suitable for multiple recycling. Using the new printing process, the packaging pattern and trademark can be more prominent, and the visual effect is outstanding.

The four-side sealing bag is resistant to cooking, moisture-proof and vacuuming. In addition to the characteristics that other packaging bags can also have, its strong anti-oxidation, anti-static and other characteristics can better protect the product from damage due to external environmental factors, high efficiency Extended shelf life.

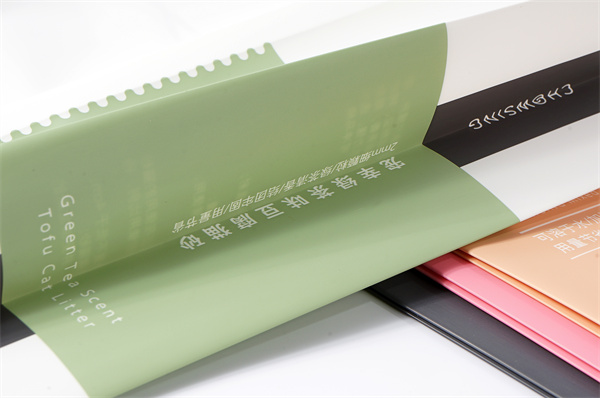

The back-sealed bag is also called a pillow-shaped bag and a middle-sealed bag. The back-sealed bag adopts hidden longitudinal sealing edge, which ensures the integrity of the front pattern of the package to the greatest extent. In the process of packaging design, the bag body pattern is set as a whole to keep the picture coherent, exquisite and beautiful, and the appearance is distinctive.

The seal of the back-sealed bag is on the back, the pressure bearing capacity of both sides of the bag is stronger, and the possibility of packaging damage is greatly reduced. The packaging bag of the same size adopts the form of back sealing, and the total length of the sealing is the smallest, which will reduce the probability of the seal cracking to a certain extent.

Finally, the back seal bag can effectively reduce the cost of packaging materials, and the consumption of consumables is small. It can reduce the consumption of packaging materials by about 40% without affecting the production speed, and the cost advantage is obvious.

And its inherent advantages of moisture-proof and waterproof, insect-proof, and anti-scattering, make the back seal bag widely used, mainly used for product packaging, storage of medicines, cosmetics, food, frozen food, etc.

There is a brief introduction to the difference between the back-sealed insert bag and the four-side-sealed packaging bag. Have all the friends who saw it learned it?

If your product needs this type of bag, please contact us quickly.

Looking forward to hearing from you.

Post time: Aug-06-2022